HRA 91~93.5 Coated Tungsten Steel Drill Bits,CNC Carbide 5XD Twist Drilling Tools

Application Field:

Tungsten Carbide 5XD Twist Drill Bits mainly used for deep hole machining, and is suitable for

processing all kinds of material,such as aluminum,non-ferrous

metals,non-metallic,and other harden steel etc.

We DROW specialize Twist Drill Bits for tens of years which can well adapt to various hole machining

demands. With our strong R&D power and advanced equipment , we

can always offer you professional and reasonable solutions to meet

your requirement as well as lower your cost.

Tools made by us can well achieve efficiency machining and long

tool lifespan.Besides, with different advanced nano coating, this

tool achieves high smooth machining surface and wear resistance.

Recommended Parameters for Tungsten Carbide Drill Cutting

Blade Diameter

D | Cutting material

(Hardness) | Linear velocity Vc m/min | feed F

mm/min | vSingle edge

cutting quantity

mm/rpm | speed S

rpm/min |

| D<4.0 | >HRC58° | Vc=20m/min | 40-60 | 0.005-0.010 | S=Vc*1000/D/3.14 |

| ≥HRC50° | Vc=20m/min | 50-70 | 0.008-0.012 |

| ≥HRC35 | Vc=30m/min | 100-150 | 0.010-0.015 |

| Stainless steel | Vc=30m/min | 100-150 | 0.010-0.015 |

| Aluminum alloy | Vc=35-65m/min | 150-300 | 0.025-0.050 |

| non-metallic | Vc=40-80m/min | 150-300 | 0.025-0.050 |

| D>4.0 | >HRC58° | Vc=30m/min | 60-100 | 0.025-0.040 |

| >HRC50° | Vc=35m/min | 80-140 | 0.030-0.050 |

| >HRC35° | Vc=50m/min | 150-300 | 0.040-0.080 |

| Stainless steel | Vc=40m/min | 100-250 | 0.035-0.080 |

| Aluminum alloy | Vc=100-150m/min | 400-800 | 0.050-0.100 |

| non-metallic | Vc=150-200m/min | 550-800 | 0.125-0.180 |

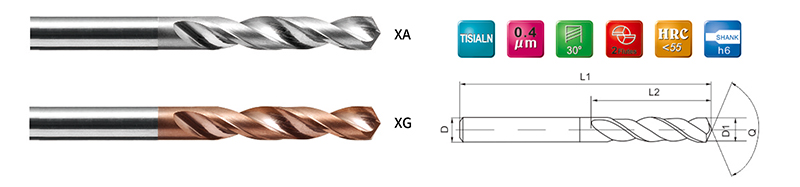

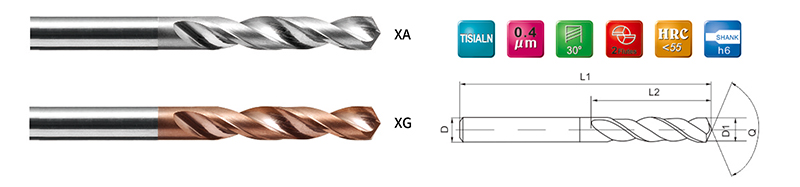

Product Details--- 5XD Carbide Drill Bits

- Tool Material : 100% virgin tungsten carbide.

- Usage: Drilling.Deep hole machining.

- Size: 5XD

- Accuracy: ±0.005mm

- Applicable materials: Uncoated tools for aluminum,non-ferrous

metals.non-metallic.Coated tools for carbon steel,alloy steel,mold

steel,other steel,ductile iron etc.

- Shank type:Milling shank, Universal Milling Shank.

- Customization:Please attach CAD drawings/3D drawings for your

inquiry, thank you.

Summary product information as below:

| Brand Name: | Drow |

| Model Number: | 5XD Metric Chamfered Carbide Drill Bits |

| Customized support: | OEM, ODM. |

| Standard: | ISO |

| Product type: | Solid Carbide Drill Bits |

| Material: | Tungsten Carbide,100% new Material |

| Coating: | To be defined per your different demands and application |

| Hardness: | HRA 91~93.5 |

| Precision: | ±0.005mm |

| Point Angle: | 118° |

| Diameter: | 0.20~16.0mm |

| Size: | 5XD |

| Surface Finish: | High Temp/Hardness AlTiN, Bright(Uncoated) |

| Shank type | Milling shank, Universal Milling Shank |

| Usage: | Deep hole machining |

| Applicable materials(Uncoated tools): | aluminum,non-ferrous metals.non-metallic |

| Applicable materials(Coated tools): | carbon steel,alloy steel,mold steel,other steel,ductile iron |

| Compatiable Machine | CNC lathes, centering machines, cutter arranging machine skateboard

lathes, turret lathes and other longitudinal lathes |

Product Features:

1.Special groove design:High-speed feed,high precision,suitable for difficult machining

conditions such as lathe machining that is easy to block.

2.Hole wall high finish: Grinded with new fine particle tungsten steel bar smooth and

sharp,not easy to stick to the knife,with high wear resistance and

strength.

3.Chamfering design:The shank chamfering design makes it easier to install the chunk.

4.Unique edge treatment:Using nano technology and advanced grinding technology, the cutting

edge of the drills sharper than before,with less cutting force,

reducing the probability of breaking the drill and improving the

quality of the hole wall.

Product Specification:

| 5XD Product parameters | unit(mm) | Spacing 0.05mm on stock |

| Order NO. | Diameter(D1) | Channel length(L2) | Full length(L1) | Shank diameter(D |

| HB-XA/XG-11(02-025) | 0.2-0.25 | 2.2 | 50 | 4 |

| HB-XA/XG-11(03-035) | 0.3-0.35 | 4 | 50 | 4 |

| HB-XA/XG-11(04-045) | 0.4-0.45 | 4.5 | 50 | 4 |

| HB-XA/XG-11(05-055) | 0.5-0.55 | 5 | 50 | 4 |

| HB-XA/XG-11(06-095) | 0.6-0.95 | 6 | 50 | 4 |

| HB-XA/XG-11(10-115) | 1.0-1.15 | 7.5 | 50 | 4 |

| HB-XA/XG-11(12-135) | 1.2-1.35 | 8 | 50 | 4 |

| HB-XA/XG-11(14-155) | 1.4-1.55 | 9 | 50 | 4 |

| HB-XA/XG-11(16-175) | 1.6-1.75 | 10 | 50 | 4 |

| HB-XA/XG-11(18-215) | 1.8-2.15 | 12 | 50 | 4 |

| HB-XA/XG-11(22-235) | 2.2-2.35 | 13 | 50 | 4 |

| HB-XA/XG-11(24-265) | 2.4-2.65 | 14 | 50 | 4 |

| HB-XA/XG-11(27-305) | 2.7-3.05 | 16 | 50 | 4 |

| HB-XA/XG-11(31-355) | 3.1-3.55 | 20 | 52 | 4 |

| HB-XA/XG-11(36-40) | 3.6-4.0 | 23 | 55 | 4 |

| HB-XA/XG-11(41-455) | 4.1-4.55 | 26 | 60 | 5 |

| HB-XA/XG-11(46-50) | 4.6-5.0 | 28 | 60 | 5 |

| HB-XA/XG-11(505-55) | 5.05-5.5 | 30 | 65 | 6 |

| HB-XA/XG-11(555-60) | 5.55-6.0 | 32 | 65 | 6 |

| HB-XA/XG-11(605-65) | 6.05-6.5 | 38 | 75 | 7 |

| HB-XA/XG-11(655-70) | 6.55-7.0 | 42 | 80 | 7 |

| HB-XA/XG-11(705-80) | 7.05-8.0 | 53 | 91 | 8 |

| HB-XA/XG-11(805-90) | 8.05-9.0 | 61 | 103 | 9 |

| HB-XA/XG-11(905-100) | 9.05-10.0 | 61 | 103 | 10 |

| HB-XA/XG-11(1005-110) | 10.05-11.0 | 71 | 118 | 11 |

| HB-XA/XG-11(1105-120) | 11.05-12.0 | 71 | 118 | 12 |

| HB-XA/XG-11(1205-130) | 12.05-13.0 | 77 | 124 | 13 |

| HB-XA/XG-11(1305-140) | 13.05-14.0 | 77 | 124 | 14 |

| HB-XA/XG-11(1405-150) | 14.05-15.0 | 87 | 133 | 15 |

| HB-XA/XG-11(1505-160) | 15.05-16.0 | 87 | 133 | 16 |

Why choose us:

1.Advanced Technology: Complex surfaces and functional structures

can be quickly formed and kept accurate.

2.Short Machining Period: Short production cycle to ensure delivery

on time according to the delivery date.

3.Crowned Product: High quality guaranteed.High precision, up to

0.005-0.001mm.

4.Confidentiality System: Triple confidentiality measures to

protect customer’s private design. Proofing more assured.

5.Fully Equipment: Excellent processing capacity, multiple

production lines, advanced equipment, professional supporting

facilities.

6.Cost-effective: Reasonable design and material selection lead us

to a competitive price, so that could help supply customers cheaper

price of the same level products .

Quality Inspection:

1.Product testing:Automatic tactile measurement of crankshaft cutter with inner

cutting edge. No matter how the alignment is, the measurement

system can measure the run out and concentricity and can be

implemented automatically

2.Tool analysis system:The software can scan the forming tool and automatically compare

the nominal value. Automatically produce test reports and record

and prove them as representative documents

FAQ

Q1:Do you produce special cutting tools?

A: Yes,we specialize in customized cutter fabricate and translate

the most complex cutting idea into reality, tools manufactured by

us are designed and customized for various demanding applications

and variety materials!

Q2:Do you accept low volume for sample order? And what’s your MOQ

for special tools?

A: Yes, we do. For sample order, MOQ one piece is accepted, and the

sample lead time is 2-3 days. It can be negotiated for special

requirement.

Q3:If we want to cooperate with you, is it possible to get

confidentiality?

A: Sure, all your information including company info, drawings, PO

details will be kept confidential, we can signed NDA if you want

(non disclosure agreement).

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show

you the photos of the products and packages before you pay the

balance.

Q5: what can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide

boring,cutting tools&customized carbide precision molds.

Q6: Who are we?

A:We are based in Guangdong Province, China, start from 2010,sell

to Western Europe(10.00%),North America(20.00%),Eastern

Europe(20.00%),Southeast Asia(40.00%),Africa(10.00%). There are

total about 51-100 people in our factory.